Implementation of failure analysis training for zero Chago engineering failures

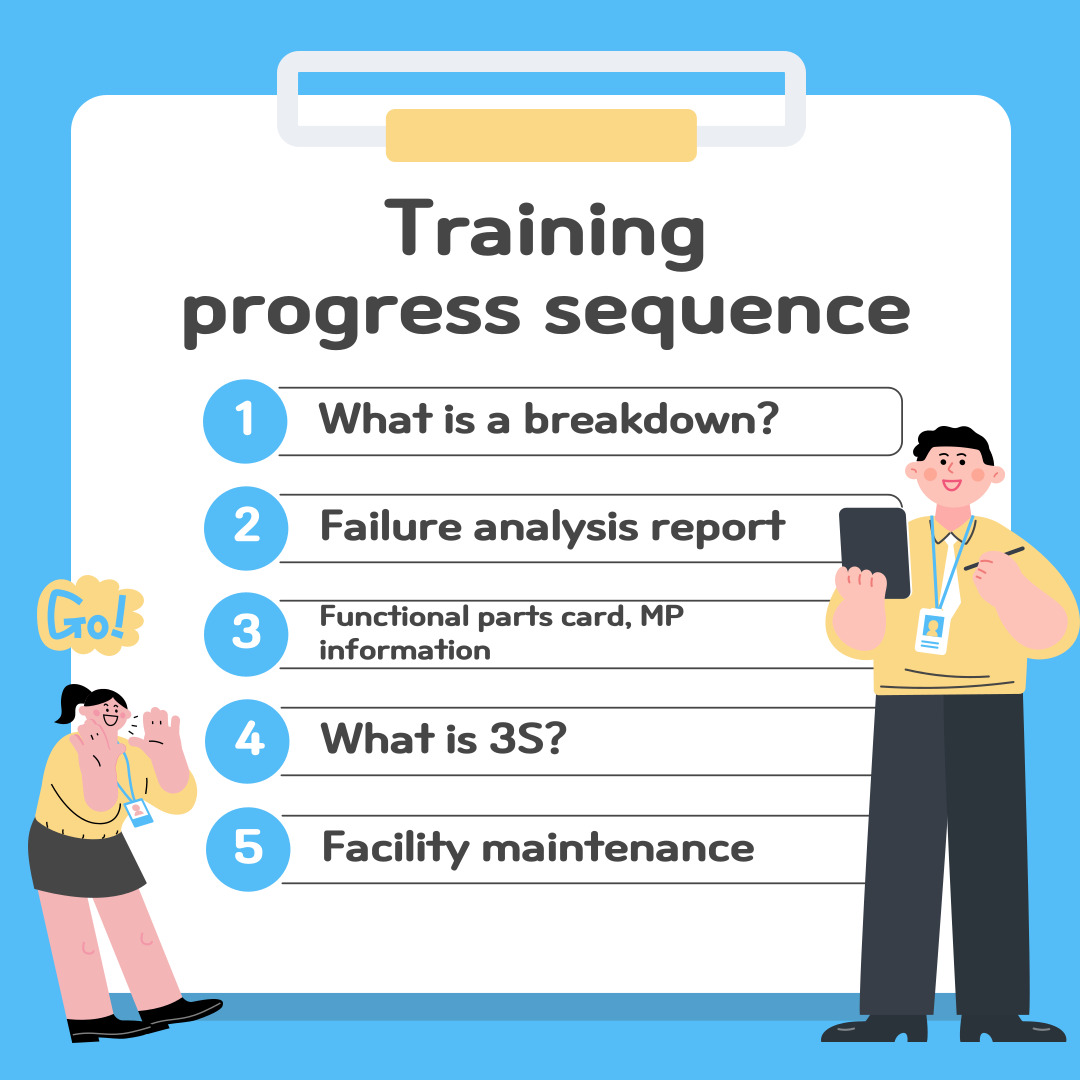

The order of training is

Explaining the meaning of failure in the semiconductor chiller field

How to write a failure analysis report and why it is important

Functional Part Card Usage and MP Information

Meaning and importance of 3S

Types and meaning of facility preservationIt proceeded in the order explained.

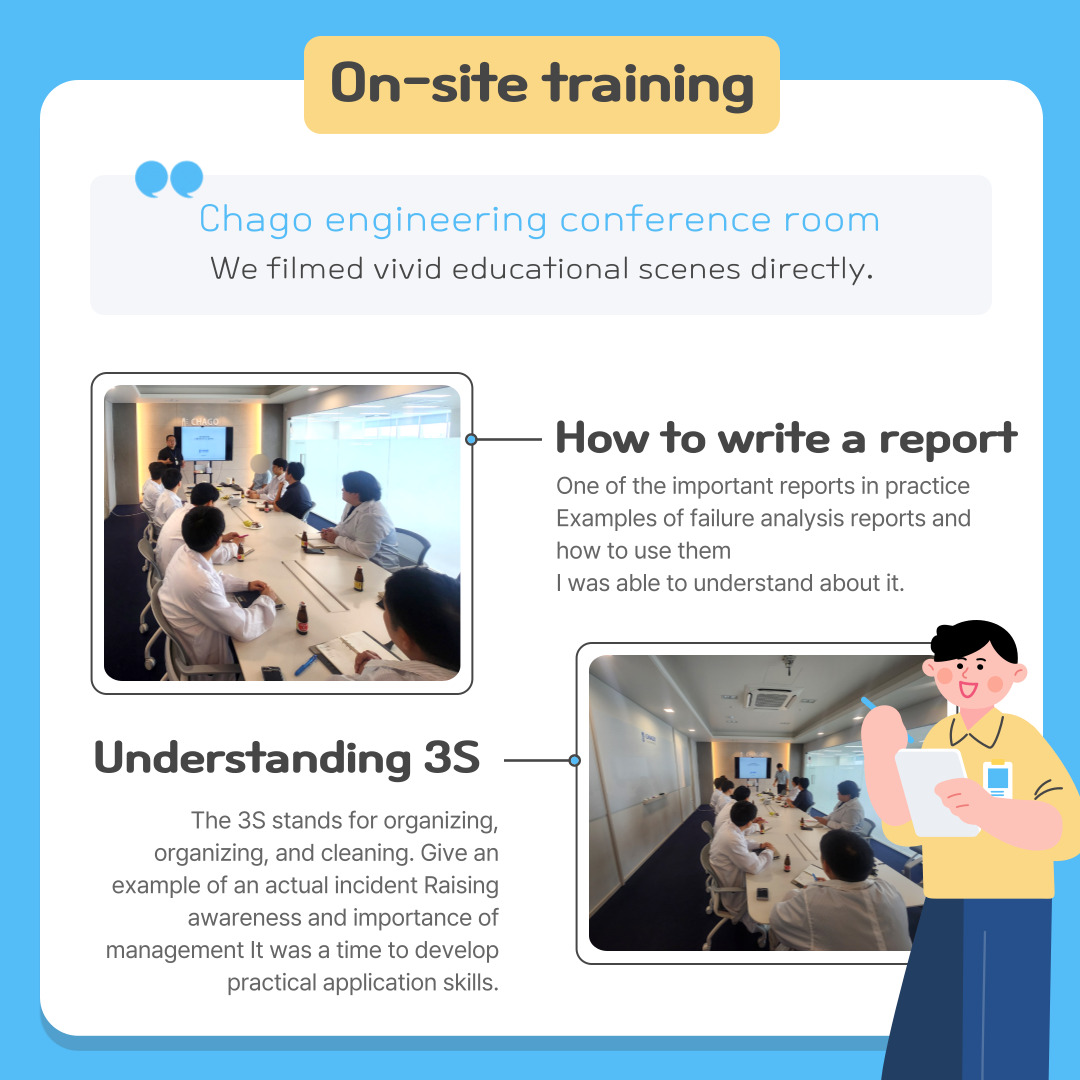

Those who participated in the training on this day included researchers from research teams 1 and 2, the director, and the CEO, and an external instructor was invited.

By bringing in semiconductor industry experts, we were able to share vivid field experiences and receive great help in realizing the importance of this training.

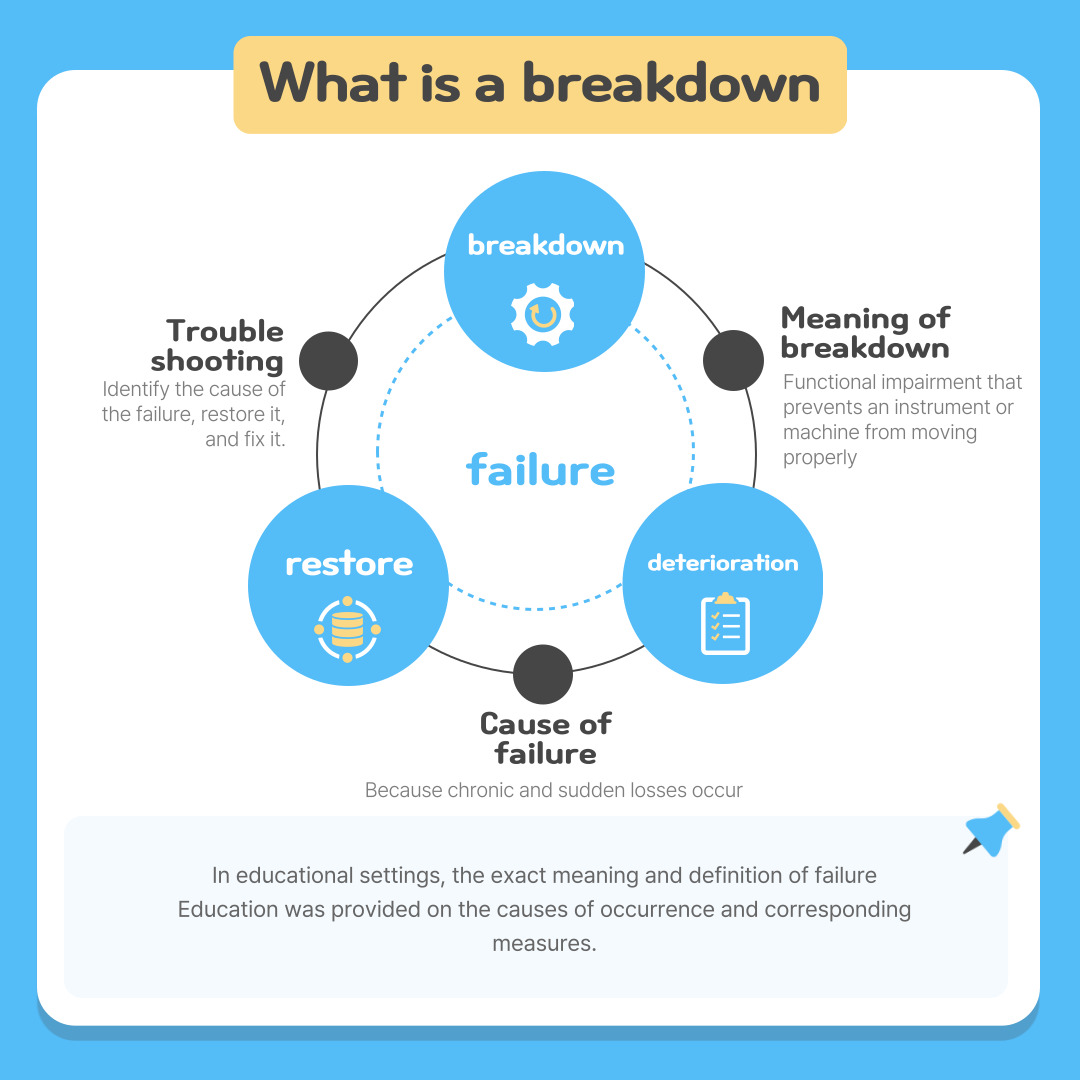

When you think of the word breakdown, you probably think of a situation where a machine is damaged or does not work for no reason.

The failures mentioned in this training have the same meaning, but semiconductor chiller production companies cover them in more detail.

It is important to determine whether the loss of equipment occurred as a chronic loss or an unexpected loss, what the cause is, and what measures are needed for restoration.

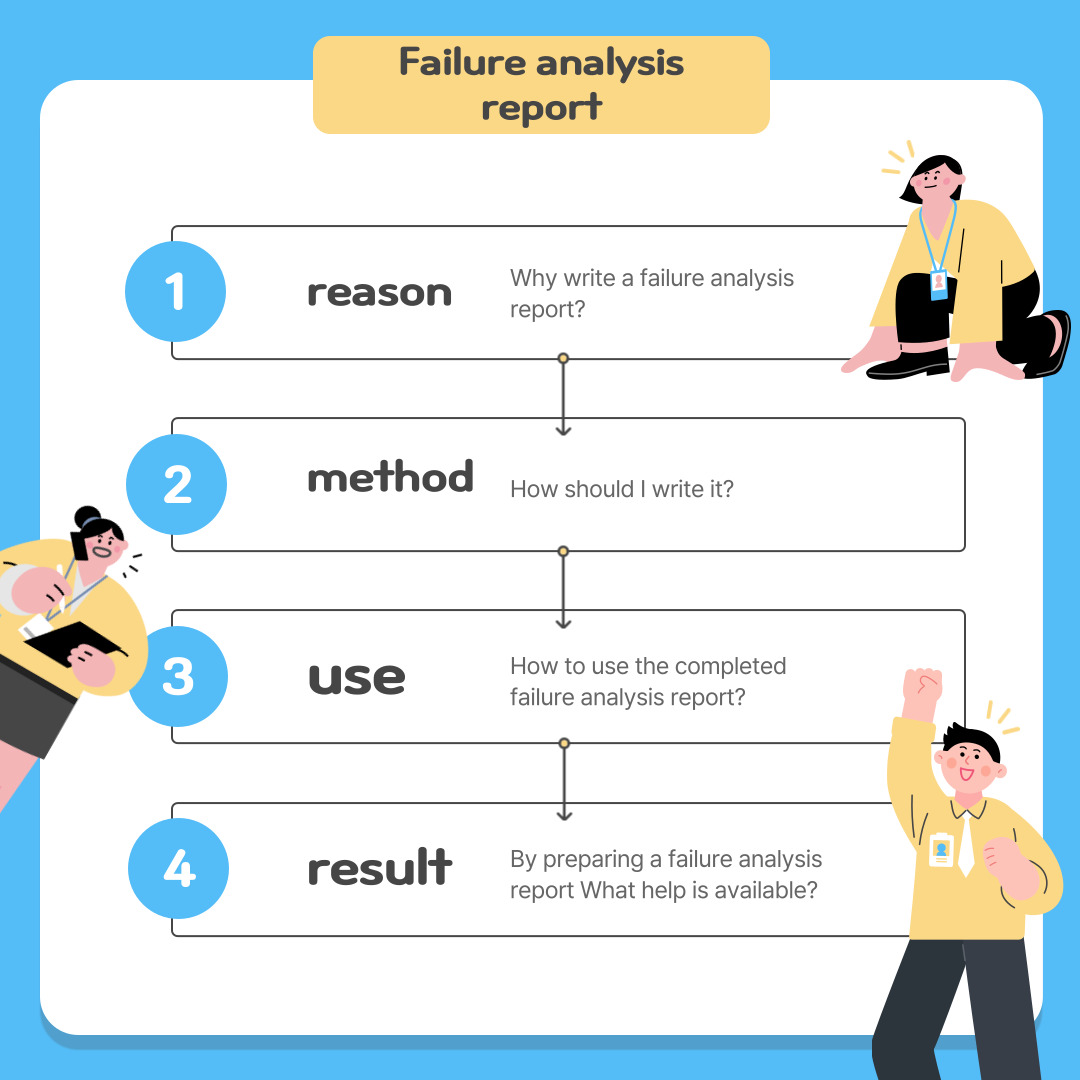

Once the cause of the failure has been identified, a failure analysis report must be prepared.

Why write it?

Analyze and share the cause of the failure, establish measures to prevent recurrence, and prevent the same failure from occurring.

This is to ensure that, even if something happens, a quick restoration is possible by identifying a restoration method.

Today, I posted about the failure analysis training conducted at Chago Engineering and the scene at the site.

It was a meaningful time because I was able to get a glimpse of the semiconductor chiller industry while watching the training site, and I was able to see how working researchers view the broken machines and facilities that we easily encounter.